Profile Automated Unloading Production Line Technical Solution

Profile Automated

- Laser power: Customized according to customer requirements

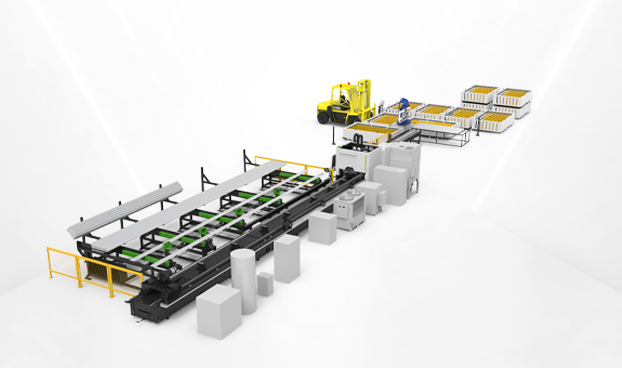

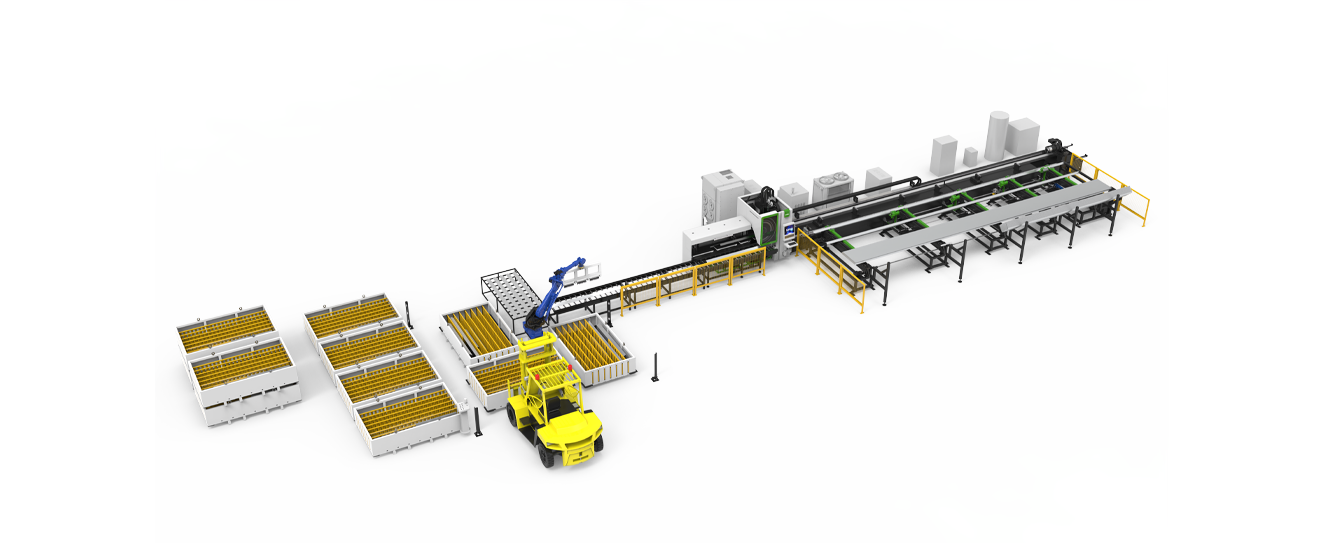

The HyTube12022A-S1 fiber laser profile cutting and stacking line includes: loading station, machine bed feeding station, machine bed cutting and marking station, unloading and conveying station, robotic stacking station, and all auxiliary equipment.

Features

Integrated multi-functions into one, create more value for customer

Precision and speed

12000W fiber laser with positioning accuracy of ±0.1mm/1000mm and repeat positioning accuracy of 0.2mm/1000mm;

Versatile material handling

Supports cutting of profiles up to 12000mm in length and Φ20-220mm in diameter;

Advanced control system

FSCUT5000 CNC control system for precise control and efficient operation;

High-quality components

German Rexroth linear guides, Neugart planetary reducer and Yaskawa servo motors, etc;

Versatile material handling

Can handle heavy loads, supporting up to 8000kg with its adaptive magnetic grippers;

Efficient workflow

Seamless workflow from loading to stacking, helping you optimize production time and minimize downtime.

Parameters

Optimize innovation to make products faster, more stable, and more reassuring

| Model number | HyTube12022A |

|---|---|

| Overall dimension | 30000*8500*2600mm |

| Working area | 12000*Φ20-220mm |

| Laser power | 12000W |

| Laser type | Fiber |

| Number of chucks | 2 |

| Chuck jaw stroke | Full stroke |

| Chuck load capacity | 200kg |

| Maximum loading length | 12000m |

| Maximum unloading length | 3000m |

| Transmission system | Rack and pinion drive |

| Drive method | Servo motor drive |

| Maximum speed | 100m/min |

| Maximum accelerated | 1.0G |

| Positioning accuracy | ±0.1mm/1000mm |

| Repeated positioning accuracy | 0.2mm/1000mm |

| Minimum surplus material length | 200mm |

| Minimum tube wall thickness for chuck clamping | ≥1mm |

| Working environment | 0-40℃ Humidity≤ 80%,non-condensing |

| Security protection measures | Light curtain, fences, etc. |

| Total equipment power | 100KW |

| Power | Three-phase 380V/50Hz |

*The appearance, parameters, performance description, data, etc. of the products displayed on this page are all from the testing and experimentation of our company's own products in the internal laboratory of Dan's Yueming Laser Factory. They are for reference only, and the actual product shall prevail.

Application

Mainly used for fast cutting of various metal materials such as carbon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, aluminum zinc plated sheet, brass, copper, etc.

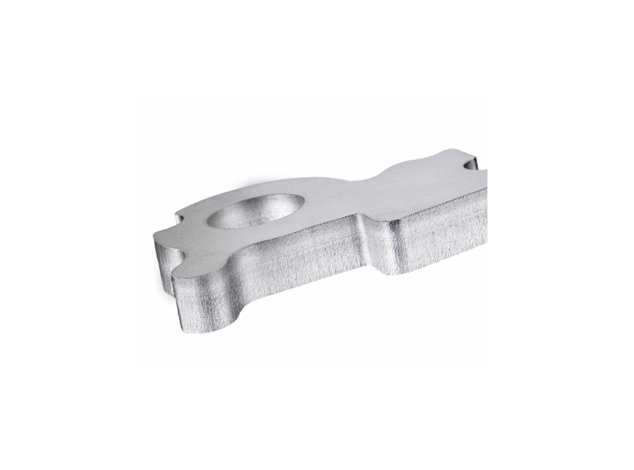

Carbon steel fiber laser cutting sample

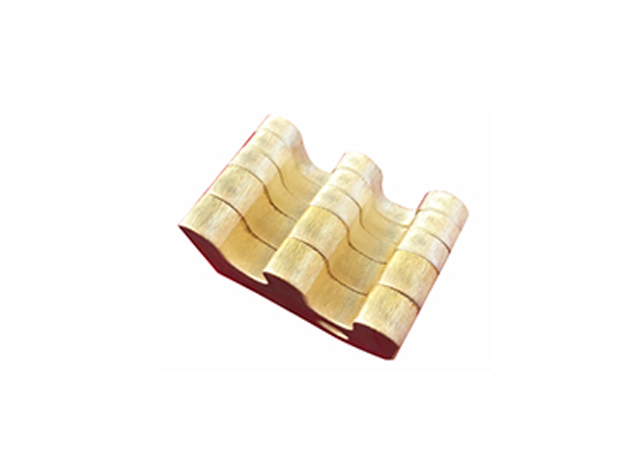

Stainless steel high-power laser cutting sample

Aluminium sheet fiber laser cutting

Copper plate high-power fiber laser cutting

Product Video

Every detail strives for perfection, with humanized operation desks, all-round design, and stainless steel edging, to create industrial products with luxury requirements to meet your needs for product appearance and taste.

Related industry

High-end field, disruptive innovation

Related Model

Opening a new era of laser intelligence

简体中文

简体中文 Spanish

Spanish Portuguese

Portuguese